ASTM is an international standards organization that is located in the United States of America. The purpose it was introduced to the industry is to publish technical standard agreements for various materials, product, systems and others. Among the ASTM standards that are often used in the industry is ASTM E8/E8M.

ASTM E8/E8M Test Standard

Description

ASTM E8/E8M is an international test standard designed for tensile testing of metallic and steel materials at room temperature (ambient temperature) between 10°C to 38°C (50 to 100 degrees Fahrenheit). Manufacturing industries such as automotive, metal, alloy, building construction and others often use this standard. Nowadays, ASTM standards are highly preferred by both corporate or government bodies. In Malaysia, most industries use the ASTM E8/E8M standard in their companies. The Malaysian government has also adopted this standard.

Basically, ASTM E8/E8M measures the strength and ductility of metal, steel, alloy and other materials under uniaxial tensile stresses. This test information is useful in comparisons of materials, alloy development, quality control, and design under certain circumstances. This ASTM is divided into two separate standards which are E8 for imperial unit users and E8M for metric users. Tensile strength tests can be performed on using Universal Testing Machine (UTM) and also known as a tensile testing machine. The following are the properties of tensile commonly measured through ASTM E8/E8M:

- Yield Strength

- Yield Point Elongation

- Tensile Strength

- Reduction of Area

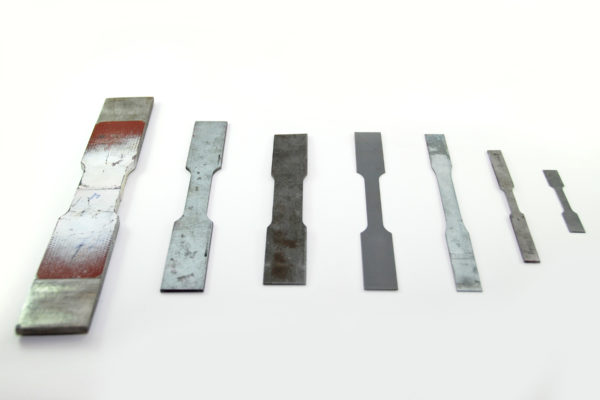

Specimens

The most common types of E8/E8M specimens are rectangular and round. For testing rectangular type specimens, it uses a flat-shaped inside grip while to test round specimens, it uses a curved inside grip. These test standards allow for many different types of specimens such as dogbone-shaped, bar, tube, sheet, plate, wire, rod, pipe, and tube. For each of these specimen types, we need to use a good and appropriate grip.

1. Round specimen 2. Threaded round specimen 3. Flat dogbone specimen

4. Wire specimen 5. Steel rod specimen

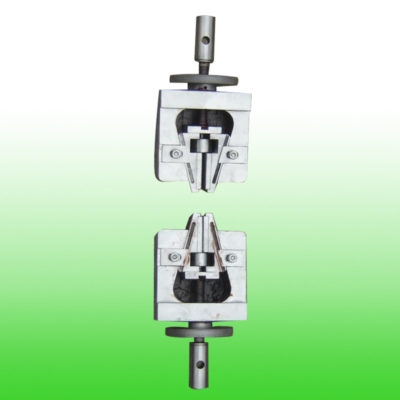

Grips

These mechanical grips are designed to self-tighten as the tensile test progresses. Used for high strength tensile testing, suitable for a flat and round specimen. Wedge grips are a popular option to be used for tensile testing on metallic materials. This is because the specimen is pulled more tightly into the narrowest area of the wedge and it will be increasing the gripping pressure.

1. Mechanical wedge grip 2. Tensile wedge grip 3. Jaw tension clamp

Extensometers

When performing a tensile test on metallic materials it requires a high-accuracy device to measure the deformation of metallic materials. It also to determine properties at lower strain values, such as modulus or yield, and a slightly lower-accuracy device for high strain values, such as uniform elongation or total elongation. Below is a type of extensometer that can be used when performing tensile tests on metallic materials.

1. Electronic extensometer

Type of UTM machine

We recommend to use UTM machines with a capacity of 50kN-100kN, it depends on the strength of the materials. We also recommend using a dual-column floor type machine.

1. VEW 2302 Series

VEW 2302 Computer Servo Type Universal Testing Machine is a new material testing machine that combined with the electronic technology and mechanical transmission, it has accurate load speed, range of force measurement, has high accuracy and sensitivity for the load, displacement measurement and control, it also can be tested the constant-velocity loading, constant- velocity displacement. This machine is simple to operate, especially suitable for controlling quality in the production line, this series of machine is mainly applied to test the non-metallic and metallic materials which the load is less than 30ton.

Main Function:

- Mainly applied to test the metallic and non-metallic materials in tension, compression, bending, shear, peel, tear or two-points extensions and others.

- Can be used for materials such as rubber, plastic, wire and cable, optical fiber and cable, safe belt, leather belt composite materials, plastic profiles, waterproof membrane, steel, copper, profiles, spring steel, bearing steel, stainless steel (as well as other high-hardness steel), castings, plate, strip, non-ferrous metal wire.

Test Procedure

- Prepare the specimens as described in the method.

- Place the specimen into grips.

- Clamp specimen at the top of the grip first then carefully clamp the sample into the bottom grip

- Attach the extensometer to the specimen

- Zero all the testing machine before starting the test

- Begin the test by Click start button on the software

- End the test after sample break (rupture)

There are different styles of grips available for different brands of equipment, but the concept is basically the same.