ASTM is an international standards organization that is located in the United States of America. The purpose it was introduced to the industries is to publish technical standard agreements for various materials, product, systems and others. Among the ASTM standards that are often use in the industries is ASTM D1002.

ASTM D1002 Test Standard

Description For ASTM D1002

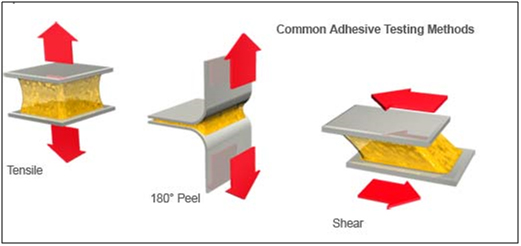

ASTM D1002 is an international test standard design for evaluating the shear strength of adhesives use for bonding metals. Manufacturing industries such as automotive, aerospace, and electronics industries often use this standard to bond various joints and subcomponents. Nowadays, ASTM standards are highly preferred by both corporate or government bodies. In Malaysia, most industries use the ASTM D1002 standard in their companies. The Malaysian government has also adopted this standard. Adhesive testing is very important in industries because to understand the relative strength of different materials.

Basically, ASTM D1002 is intended to be primarily comparative in nature as it cannot be correlated to real-world performance. In real-world applications, changes in non-uniform environmental conditions will contribute to adhesive performance variations. The shear strength of adhesives tests can be perform on using Universal Testing Machine (UTM).

Test control

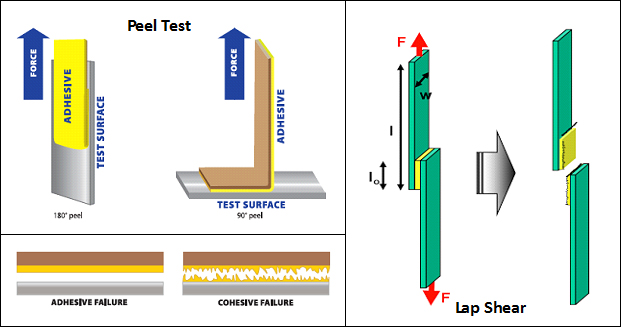

To perform this test, both ends of the adhered specimen will be pulled in tension until the specimen failure. When this test is perform, the tensile force apply to the specimen will turn into shear stress. This shear stress occurs in the entire adhered area.

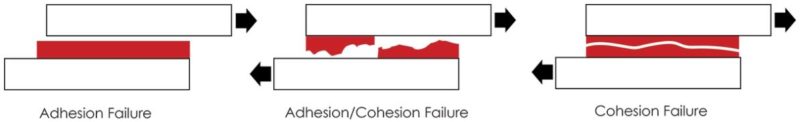

Usually, the results will include the failure load. The following is one of the three types of failures recorded:

- The cohesion of adhesive – failure occurs within the adhesive

- Adhesion to the substrate – failure occurs at the bond between the adhesive and the substrate

- Combination failure – failure occurs within both the adhesive and adhesive-substrate bond

The ASTM D1002 requires two uses, either a fixed/constant stress rate or an equivalent displacement rate. To perform a fixed/constant stress rate, it use closed-loop feedback between the loadcell and controller. The loadcell need to be adjust to achieve the desired stress rate.

Specimens For ASTM D1002

- The adhesive used for bonding metals

- Commonly used in the automotive, aerospace & electronics industries

Grips For ASTM D1002

1. Pneumatic Grip

Pneumatic grips are particularly useful when a variety of materials. The gripping force is generate by pneumatic cylinders acting directly on the jaws or via a lever system.

2. Side screw action grip

Suitable to test fabric, textile webbing, metal, film, rubber and plastic.

Extensometers For ASTM D1002

This test does not require an extensometer because the purpose of this test is not to measure the displacement of elongation.

Type of UTM machine

We recommend to use UTM machines with a capacity of 2kN-100kN, it depends on the strength of the adhesive

1. VEW 2308

The machine is design by mechanical-electrical integration, the composition of the force-measuring Sensor, transmitter, microprocessor, mechanism of load drive, computer and color inkjet printer. The high-precision electronic motor can be set to five-speed, the components are connect by plug-way, Floor-standing models, it is taken account of modern industrial design and ergonomics in modelling and Coating.

It can be test with all the materials in the stretch, compression, bending, shear, embedded relay, Peeling. tearing, crack, etc, such as rubber, plastics, leather, metal, nylon wire, fabric, paper, aerospace, packaging, construction, petrochemical, electrical, vehicle, etc.

The implementation of standards and standard configuration:

- GB/T4689.20-1996 Measuring fastness of leather’s adhesion

- QB/T2710-2005 Measuring leather’s expansion and the rate of elongation

- QB/T2711-2005 measuring tear force of leather

- QB/T2712-2005 measuring leather’s strength and stretch of spherical crack test

2. VEW 2307

VEW 2307 Desktop microcomputer-type tensile testing machine is designed by our company which is made of aluminium, it is not only small, used widely, do not take up space, nice appearance, but also easy to move with the hoop, it is very convenient to operate.

- It is control by computer and printing out the testing report; the outward appearance used the closing board dealing with high-level baking varnish, which obviously elegant

- It especially suitable for controlling quality in the production line, this series of machine is mainly apply to test the non-metallic and metallic materials which the load is less than 2KN

3. VEW 2302 Series

VEW 2302 Computer Servo Type Universal Testing Machine is a new material testing machine that combined with the electronic technology and mechanical transmission, it has accurate load speed, range of force measurement, has high accuracy and sensitivity for the load, displacement measurement and control, it also can be tested the constant-velocity loading, constant- velocity displacement.

This machine is simple to operate, especially suitable for controlling quality in the production line, this series of machine is mainly apply to test the non-metallic and metallic materials which the load is less than 30ton.

Main Function:

- Mainly apply to test the metallic and non-metallic materials in tension, compression, bending, shear, peel, tear or two-points extensions and others.

- Can be use for materials such as rubber, plastic, wire and cable, optical fiber and cable, safe belt, leather belt composite materials, plastic profiles, waterproof membrane, steel, copper, profiles, spring steel, bearing steel, stainless steel (as well as other high-hardness steel), castings, plate, strip, non-ferrous metal wire.