ASTM is an international standards organization that is located in the United States of America. The purpose it was introduced to the industry is to publish technical standard agreements for various materials, product, systems and others. Among the ASTM standards that are often use in the industry is ASTM D143.

ASTM D143 Test Standard

Description For ASTM D143

ASTM D143 is an international test standard design for determine the strength and related properties of wood by testing small clear specimens. These test methods represent procedures for evaluating the different mechanical and physical properties, controlling factors such as specimen size, moisture content, temperature, and rate of loading.

Basically ASTM D143 mechanical tests are:

• Bending

• Toughness

• Hardness

• Shear parallel to grain

• Cleavage

• Tension parallel to grain

• Tension perpendicular to grain

• Nail withdrawal

These tests may be made on both green and air dry material as specified in these test methods. In addition, test methods for evaluating such physical properties as specific gravity, shrinkage in volume, radial shrinkage, and tangential shrinkage are present.

Specimen For ASTM D143

1. Wood

Grips For ASTM D143

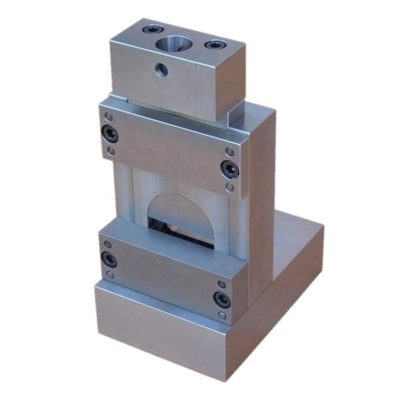

1. Wood tensile fixture

ASTM D143 tensile testing perpendicular to the wood grain test requirements which describes the size and shape of the grips used for tension testing wood specimens perpendicular to the grain. In the test, a timber specimen is cut into shape and place into the fixture.

A tensile test is conducted and the resulting tensile strength and maximum load are analyzed. The grips are made from precisely machined, high strength tool steel.

2. Shear test fixture

Describes test grips for determining the adhesive bond strength of wood and similar materials. A compressive loading is apply to generate the shear stress, and two rectangular blocks of equal size, staggered 1/4″, are bonded together. A guillotine-type loading is apply to shear off one block from the other.

Type of UTM machine

We recommend using UTM machines with a capacity of 5kN-600kN. It depends on the strength of the materials. We also recommend using dual-column types.

1. VEW 2308

The machine is design by mechanical-electrical integration, the composition of the force-measuring Sensor, transmitter, microprocessor, mechanism of load drive, computer and color inkjet printer.

The high-precision electronic motor can be set to five-speed, the components are connect by plug-way, Floor-standing models, it is taken account of modern industrial design and ergonomics in modelling and Coating.

It can be tested with all the materials in the stretch, compression, bending, shear, embedded relay, Peeling. tearing, crack, etc, such as rubber, plastics, leather, metal, nylon wire, fabric, paper, aerospace, packaging, construction, petrochemical, electrical, vehicle, etc.

The implementation of standards and standard configuration:

- GB/T4689.20-1996 Measuring fastness of leather’s adhesion

- QB/T2710-2005 Measuring leather’s expansion and the rate of elongation

- QB/T2711-2005 measuring tear force of leather

- QB/T2712-2005 measuring leather’s strength and stretch of spherical crack test

Test Procedure For ASTM D143

This standard contains test methods for determining the various strength and elastic properties of wood through 8 different mechanical tests

-

Impact bending

1. Make the tests by increment drops in a hatt-turner or similar impact machine

2. The first drops shall be 1 in.(25mm), after which increase the drops by 1 in. increments until a height of 10 in. (250 mm) is reached.

3. Then use a 2 in.(50mm) increment until complete failure occurs or a 6 in.(150mm) deflection is reach. -

Toughness

1. Make the tests in a pendulum type toughness machine machine.

2. Adjust the machine before test so that the pendulum hangs vertically and adjust it to compensate for friction

3. Adjust the cable so that the load is apply to the specimen when the pendulum swings to 15˚ from the vertical, so as to procedure complete failure by the time downward swing is complete.

4. Choose the weight position and initial angle (30, 45, or 60˚) of the pendulum, so that complete failure of the specimen is obtained on one drop.

5. Most satisfactory results are obtained when the difference between the initial and final angle is at least 10˚ -

Hardness

1. Use the modified ball test with a “ball” 0.444 in. (11.3 mm) in diameter for determining hardness

2. The projected area of the ball on the test specimen is 1cm²

3. Record the load which the ball has penetrated to one half its diameter, as determine by an electric circuit indicator or by the tightening of the collar against the specimen -

Shear parallel to grain

1. Use a shear tool, providing 1/8 in. (3mm) offset between the inner edge of the supporting surface and the plane of the adjacent edge of the loading surface.

2. Apply the load to and support the specimen on end-grain surfaces.

3. The shear tool shall include an adjustable crossbar to align the specimen and support the back surface at the base plate - 4. Take care in placing the specimen in the shear tool to see that the crossbar is adjust , so that the edges of the specimen are vertical and the end rest evenly on the support over the contact area

5. Observe the maximum load only -

Cleavage

1. The specimen shall be held during test in grips (cleavage test assembly)

2. Observe the maximum load only -

Tension parallel to grain

1. Fasten the specimen in special grips

2. Deformation shall be measure over 2 in. (50mm) central gage length on all specimen

3. Take load extension readings until the proportional limit is pass. -

Tension perpendicular to grain

1. Fasten the specimens during test in grips

2. Observe the maximum load only -

Nail withdrawal

1. Withdraw all six nails in a single specimen immediately after driving

2. Fasten the specimens during the test in grips

3. Observe the maximum load only

Measurements For ASTM D143

1. Measurements of test specimens shall be made to an accuracy of not less than 0.3%, except that in no case shall the measurements be made less than 0.01 in. (0.25mm).2. Measurements of radial and tangential shrinkage specimen shall be made to the nearest 0.001 in. (0.02mm)

Check out our other blogs:

-

ASTM A938 Test Standard ( Torsion Test Of Metallic Wire)

-

ASTM D2256 Test Standard

-

The Comprehensive Guide To ASTM D412 Elastomer Tensile Testing