ASTM is an international standards organization that is located in the United States of America. The purpose it was introduced to the industry is to publish technical standard agreements for various materials, product, systems and others. Among the ASTM standards that are often use in the industry is ASTM D3330.

ASTM D3330 Test Standard

Description For ASTM D3330

ASTM D3330 is an international test standard design to determine the adhesive strength of pressure-sensitive tapes. Manufacturing industries such as duct tape, electrical tape, masking tape, packaging, double-sided tape, bandages, medical devices, and others often use this standard. Nowadays, ASTM standards are highly preferred by both corporate or government bodies. In Malaysia, most industries use the ASTM D3330 standard in their companies. The Malaysian government has also adopted this standard.

Basically, ASTM D3330 measures the peel adhesion of pressure-sensitive tapes. This test method is use for assessing the uniformity of the adhesion of a given type of pressure-sensitive adhesive tape. The assessment can be done within a roll of tape, between rolls, or between production lots. This test can be perforM on using Universal Testing Machine (UTM).

These test methods provide a means of assessing the uniformity of the adhesion of a given type of pressure-sensitive adhesive tape. The assessment may be within a roll of tape, between rolls, or between production lots.

Specimens For ASTM D3330

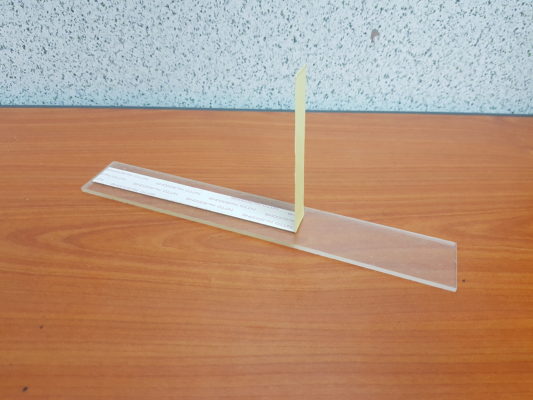

1. Peel test specimen (adhesive)

Grips For ASTM D3330

1. Adhesive peel test grip

2. Side action grip

Suitable to test fabric, textile webbing, metal, film, rubber and plastic

3. Pneumatic Grip

Pneumatic grips are particularly useful when a variety of materials. The gripping force is generate by pneumatic cylinders acting directly on the jaws or via a lever system.

Type of UTM machine

We recommend to use UTM machines with a capacity of 50N-20kN, it depends on the strength of the adhesive. We also recommend using smaller machines such as single column or dual column floor types.

1. VEW 220E

VEW 220E desktop computer servo testing machine is a new material testing machine that combine with the electronic technology and mechanical transmission, it has accurate load speed, range of force measurement, Has high accuracy and sensitivity for the load, displacement measurement and control. This series of machine using single-space structure, operational space at the bottom, it is mainly apply to test non-metallic and metallic material, which the load is less than 1kN, it has the parameters, such as stress, strain, the control mode of displacement, calculated max force, tensile strength, bending strength, compressive strength, elastic modulus, rate of elongation, yield strength and others.

Main function:

This machine can be apply to test lots of materials in tension, compression, tear, peel (can 90 degrees and 180 degrees) and other mechanical tests, such as rubber, tires, belt, shoes, plastic, film, acrylic, FRP, ABS, EVA, PU, aluminium-plastic pipe, composite materials, waterproof materials, fibers, textiles, wire and cable, paper, gold foil, ribbons, thread, spring, wood, medicine packaging materials, tapes etc.

2. VEW 2307

VEW 2307 Desktop microcomputer-type tensile testing machine is designed by our company which is made of aluminium, it is not only small, used widely, do not take up space, nice appearance, but also easy to move with the hoop, it is very convenient to operate.

- It is control by computer and printing out the testing report; the outward appearance use the closing board dealing with high-level baking varnish, which obviously elegant

- It especially suitable for controlling quality in the production line, this series of machine is mainly applied to test the non-metallic and metallic materials which the load is less than 2KN

3. VEW 2308

The machine is design by mechanical-electrical integration, the composition of the force-measuring Sensor, transmitter, microprocessor, mechanism of load drive, computer and color inkjet printer. The high-precision electronic motor can be set to five-speed, the components are connected by plug-way, Floor-standing models, it is taken account of modern industrial design and ergonomics in modelling and Coating. It can be tested with all the materials in a stretch, compression, bending, shear, embedded relay, Peeling. tearing, crack, etc, such as rubber, plastics, leather, metal, nylon wire, fabric, paper, aerospace, packaging, construction, petrochemical, electrical, vehicle, etc.

The implementation of standards and standard configuration:

- GB/T4689.20-1996 Measuring fastness of leather’s adhesion

- QB/T2710-2005 Measuring leather’s expansion and the rate of elongation

- QB/T2711-2005 Measuring tear force of leather

- QB/T2712-2005 Measuring leather’s strength and stretch of spherical crack test

Test Procedure

This test standard has 6 different methods. It consists of Methods A, B, C, D, E and F. These methods use to identifying ways to measure peel adhesion with 180-degree and 90-degree peel methods. The following are some of the methods:

Test Method A gives a measure of the adherence when peeled at 180° angle, to a standard steel panel or to another surface of interest for a single-coated tape.

Test Method B gives a measure of the adherence to the backing of a single-coated tape.

Test Method C gives a measure of the adherence of double-coated tape to a standard steel panel or another surface of interest.

Test Method D gives a measure of the adherence of the release liner to the adhesive of either single- or double-coated tape.

Test Method E gives a measure of the adherence of an adhesive transfer tape to a standard steel panel or another surface of interest.

Test Method F gives a measure of the adherence when peeled at 90° angle, to a standard steel panel or another surface of interest for a single-coated tape.