ASTM is an international standards organization that is located in the United States of America. The purpose it was introduced to the industry is to publish technical standard agreements for various materials, product, systems and others. Among the ASTM standards that are often use in the industry is ASTM D905.

ASTM D905 Test Standard

Description For ASTM D905

ASTM D905 allows for the study of shear strengths of adhesives used for bonding wood and other similar materials. Like other test methods involving wood, a lot of care has to be taken into account in regards to the specimen selection, conditioning, moisture content, temperature, etc. when attempting to compare results of these tests. This test is employed by companies that manufacture products such as wood glue. Glues and adhesives are increasingly use in the construction of products in order to aid in manufacturability as well as light weighting. A small amount of glue is much lighter than a bolt and screw and much easier for a robot or machine to apply.

Specimen For ASTM D905

- Wood

Grips For ASTM D905

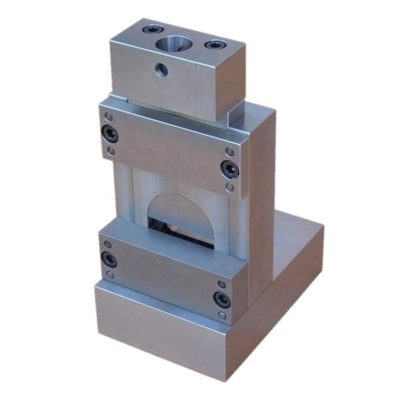

- Shear test fixture

Describes test grips for determining the adhesive bond strength of wood and similar materials. A compressive loading is apply to generate the shear stress, and two rectangular blocks of equal size, staggered 1/4″, are bonded together. A guillotine-type loading is apply to shear off one block from the other.

Type of UTM machine

We recommend using UTM machines with a capacity of 5kN-600kN. It depends on the strength of the materials. We also recommend using dual-column types.

- VEW 2308

The machine is design by mechanical-electrical integration, the composition of the force-measuring Sensor, transmitter, microprocessor, mechanism of load drive, computer and color inkjet printer. The high-precision electronic motor can be set to five-speed, the components are connect by plug-way, Floor-standing models, it is taken account of modern industrial design and ergonomics in modelling and Coating. It can be test with all the materials in the stretch, compression, bending, shear, embedded relay, Peeling. tearing, crack, etc, such as rubber, plastics, leather, metal, nylon wire, fabric, paper, aerospace, packaging, construction, petrochemical, electrical, vehicle, etc.

The implementation of standards and standard configuration:

- GB/T4689.20-1996 Measuring fastness of leather’s adhesion

- QB/T2710-2005 Measuring leather’s expansion and the rate of elongation

- QB/T2711-2005 measuring tear force of leather

- QB/T2712-2005 measuring leather’s strength and stretch of spherical crack test

Test Procedure

- Prepare and condition the test specimen in accordance with the test standard. The test specimen consists of two blocks of wood bonded to each other with a slight offset.

- Place the test specimen in a shearing tool mounted in a test machine capable of applying a compressive load. The dimensions of the shearing jig require for this test are defined within the standard

- Apply a compressive load to the specimen at the constant position rate specified within the standard.

- Continue loading until failure.

Measurements

- Shear Stress