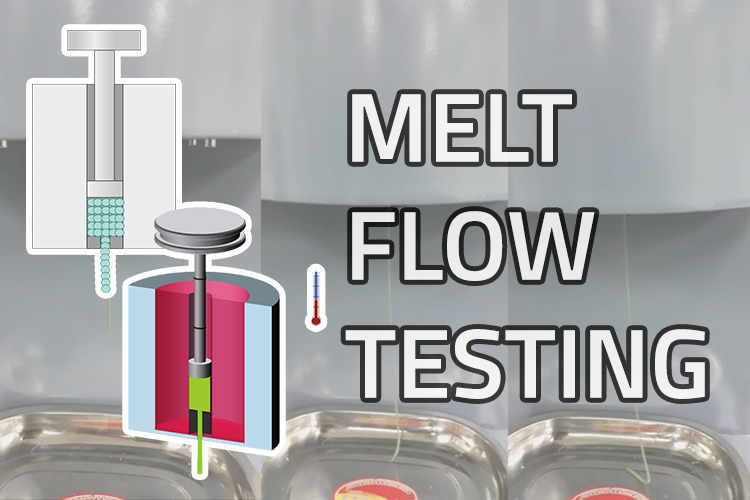

Melt flow testing measures the ease of flow on the melted thermoplastic* to predict how their resins/pellets will behave in their intended applications. This allows product designers, researchers, manufacturers, and even quality control managers to discover the overall quality and production rate capability of that polymer.

*A type of polymer that is easily remolded and recycled because its polymer chain does not degrade when it is being melted; even as its cools after the melting process.

BENEFITS

It is important for quality checking the next batch of plastic resins to :

- Evaluate & Analyse new material from suppliers

- Estimate the flow rate for a simple extrusion process

- Predict how a polymer behaves under various melt flow rate processes

- Verify the in-house material (Melt Flow Index identification)

- Quality check, compare & differentiate for each raw material batch

- Determine if the new batch of plastic raw materials (plastic resin) provided by their supplier is up to customer’s requirements, industry standards, and whether it is suitable for the extrusion machine used during the production process

INDUSTRY APPLICATION

- Universities & Education Facilities

- Research & Development Sector

- Plastic Product & Raw Material Manufacturers

HOW TO MEASURE MELT FLOW?

Melt Flow Indexer (MFI) is specialised equipment that allows melt flow testing on thermoplastic resins. You can view our list HERE.

Want Consultation or Equipment on Melt Flow Testing?

Reach out to our expert today for a professional recommendation.

Alvin George, Product Specialist (+6012-2232593)

[email protected] cc [email protected]

- Browse our Material Testing Equipment via www.victormaterial.com

- View our list of Services at www.victortestingmachine.com