VIR-300 Computer control Pendulum Impact Testing Machine were strictly designed

according to national standard GB/T3038-2002 “Inspection for pendulum Impact

Testing Machine” and GB/T229-1994 “Charpy notch Impact Test Method for metal

material”. It is also accordance with international standard ISO148-1983,ASTM E23 and

EN10045. It is mainly used to determine the anti-impact capability of metal materials

under dynamic load. Carry out the functions of clear zero and return automatically,

capture the value of lost impact energy and pendulum cycle by means of setting up

with computer program, and the result can be displayed, stored and printed out. Hand

box and computer program controlled alternative operating method.

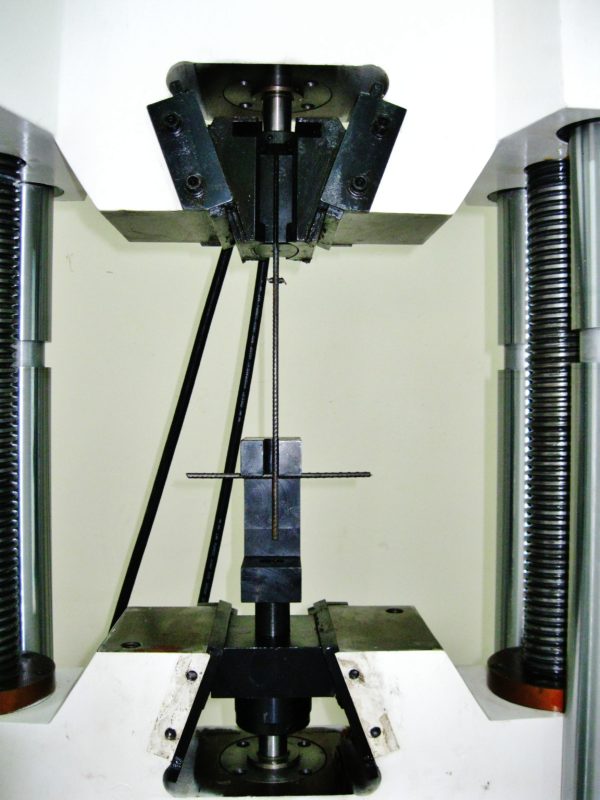

HZ-1701 Semi-automatic Charpy Impact Tester

1.Impact energy: 150J, 300J

2.Pendulum moment: M300=160.7696N.m; M150=80.3848N.m

3.Impact velocity: 5.2m/s

4.Distance from the center of the pendulum shaft to the impact point: 750mm

5.The Span of sample support: 40 mm

6.Impact knife thickness: 16mm

7.Raised angle :150º

8.Standard span: 40mm

9.Round angle of jaws: R1-1.5mm

10.Round angle of striking Edge: R2-2.5

11. Size of specimen: 10 x 10 x 55mm or 10 x 7.5 x 55mm or 10 x 5x 55mm, etc.

12. Power supply: 3 phs, 380V, 50Hz, 180W

13. Dimensions: 2044 x 736 x 1390mm

14. Net Weight: 450kG

15. Display: Computer Screen Display and dial display.