Application

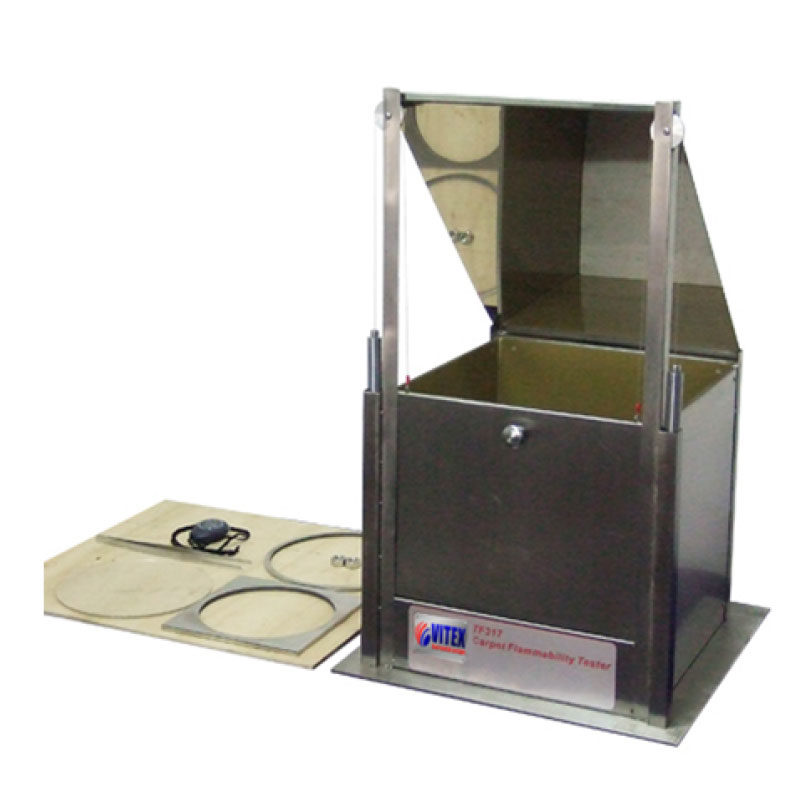

Carpet Flammability tester is used to test the effects of a small source of ignition on floor coverings. Carpet flammability tester can be used for either hot metal nut test (BS 4790) and Methenamine tablet test (ISO 6925, BS 6307 and GB/T 11049).

- Test methods (Hot metal nut method, BS 4790)

The stainless steel nut is heated to 900℃ in a muffle furnace, place specimen on the bottom of the test chamber and the clamping ring is placed on the specimen, use crucible tongs to place the heated nut in the center of the ring, remove the nut in 30s and a measurement of spreading of the ignition on the sample is made to evaluate the flammability of carpet - Test methods (Methenamine tablet method, ISO 6925, BS 6307)

Place the conditioned specimen on the removable base inside the test chamber and the metal plate with a circular cut-out is placed on the specimen, the tablet is placed at the centre of the specimen and ignited. After the flame has extinguished, measurements are made to assess the effect on the carpet.

Optional order

- Muffle furnace

- M16 nut

- Methanamine tablets

Standards

ISO 6925, BS 4790, BS 6307, CFR 1630/1631, GB/T 11049, CPAI 84, CGSB standard 4-GP-2

Weight

40 Kg

Dimensions

500 x 500 x 850 mm (L x W x H)