Application

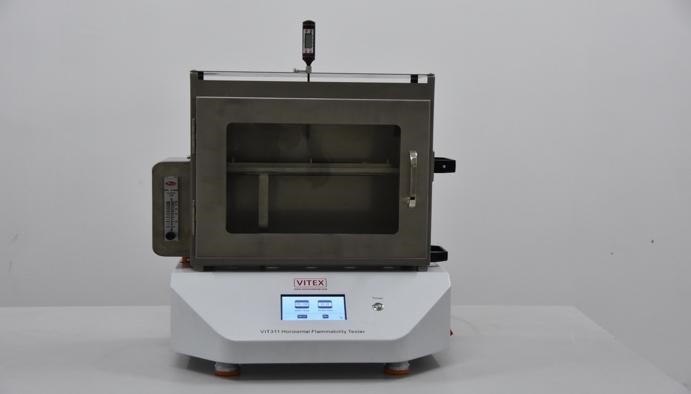

Horizontal Flammability Tester, to determine the comparative burn rates and burn resistance of textiles, particularly those for automotive interior use. Automatic igniter is equipped to ensure the horizontal flammability tester is safe and easy to operate, comprising draft free stainless steel cabinet with observation window, sample holder and door mounted burner.

Standards

ISO 3795, FMVSS 302, DIN 75200, SAE J369, ASTM D5132, JIS D1201, BSAU 1690, GB 8410, PSA-Renault standard D45 1333

Power

220 /110 V 50/60 Hz 2 A

Weight

40 Kg

Dimensions

550 x400 x 770mm (L x W x H)