Application

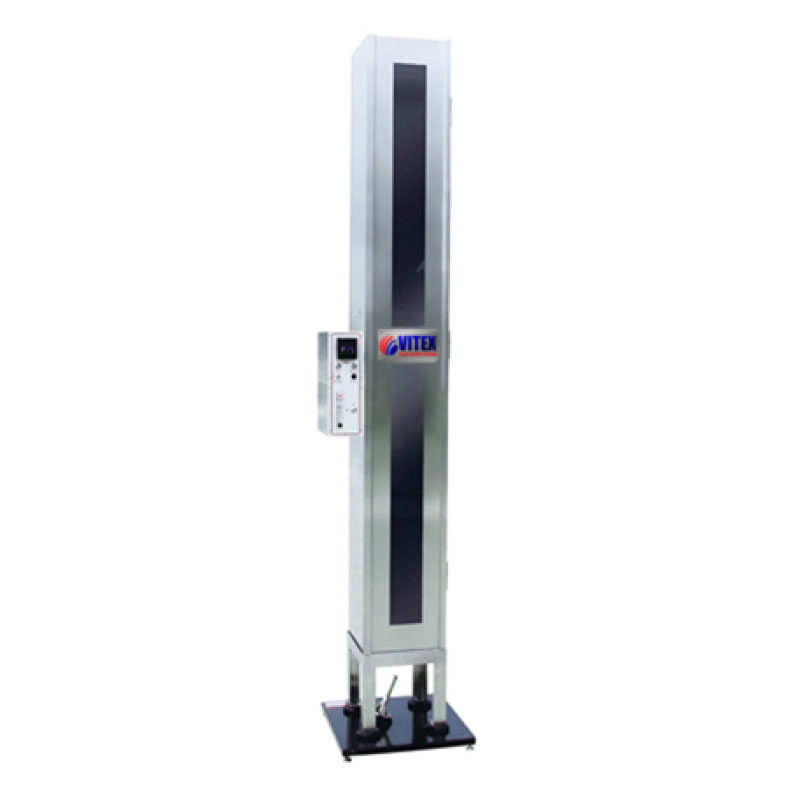

NFPA 701-2 Flammability Tester, to determine the ignition resistance properties of draperies and other hanging fabrics according to test method NFPA 701#2, and it is suitable for single-layer or multi-layer fabrics, fabrics with density larger than 700g/m2 (21oz/yd2), and fabrics coating with polyethylene, etc.

Standards

NFPA 701-2004/2010 Test Method 2.

Power

220 /110 V 50/60 Hz 3 A

Weight

110 Kg

Dimensions

440 x 410 x 2500mm (L x W x H)