Application

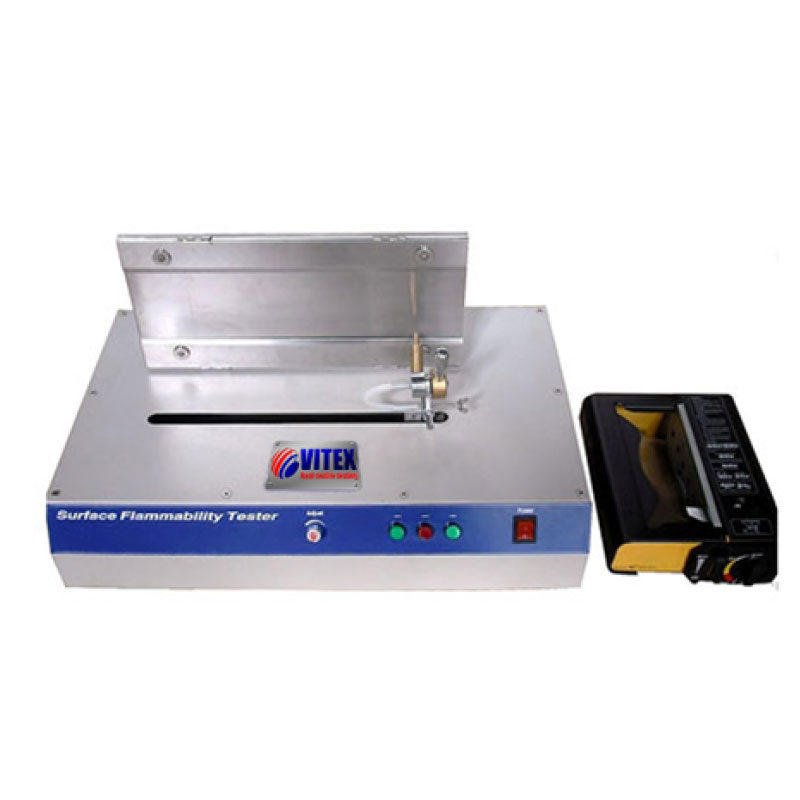

Surface Flash Tester. The rapid spread of flame over the surface of the material without ignition of its basic structure, is usually applied to pile or fur fabrics. This flammability tester is safe and easy to operate. Swiveling butane burner is traversed across the face of the fabric to determine whether surface flash occurs and to record any damage to the base fabric.

Automatic gas and timing control system includes solenoid control gas valve and automatic ignition timer and controls.

Standards

BS 4569

Power

220 /110 V 50/60 Hz

Weight

45 Kg

Dimensions

450 x 400 x 300 mm (L x W x H)