How to Conduct a Tensile Test on Elastomers according to ASTM D412

ASTM D412

The ASTM D412 rubber and elastomer tensile test is a standard test that was create to test the efficiency of rubber and elastomeric materials. When samples is subject to an applied external force, the test aims to provide a comprehensive measure of the elongation or change in length that happens.

This guide is design to introduce you to the basic elements of an ASTM D412 tensile test and will provide an overview of the materials testing equipment, software, and samples needed. We recommend obtaining the ASTM D412 test standard ASTM if you plan on performing the tests.

Every standard specifies critical environmental conditions, as well as test sample preparation and conditioning criteria, sample dimensions, and test reporting requirements such as ASTM D412.

WHAT IS ASTM D412

The test equipment and procedures required to test the tensile (tension) properties of vulcanized thermoset rubbers and thermoplastic elastomers are describe in ASTM D412.The preparation of samples and testing specimens are the first steps in determining tensile characteristics.

WHAT DOES ASTM D412 MEASURE?

ASTM D412 determines a material’s elasticity while under tensile strain, as well as its behavior after the test is complete and the material is no longer stressed. ASTM D412 is tested at a rate of 500mm/min on a universal testing machine (also known as a tensile testing machine) until the specimen fails.

Among the several tensile qualities measure by ASTM D412, the following are the most common:

Tensile Strength: The maximum tensile stress that can be given to a specimen before it ruptures.

Ultimate Elongation: The elongation at which rupture occurs in the application of continue tensile stress.Tensile Stress at particular Elongation.

Tensile set: The extension remains after a specimen has been stretched and allowed to retract in a specified manner, expressed as a percentage of the original length.

ASTM D412 TESTING EQUIPMENT

The majority of ASTM D412 testing is done on a tabletop-type universal testing machine that may be customized to appropriately execute an ASTM D412 tension strength test for elastomers and rubber.

For ASTM D412, we recommend Model VEW260E Extended Version along with accessories such as a long travel extensometer, and a pair of manual roller grips. A sample ASTM D412 test setup is pictured below.

TEST METHOD OF ASTM D412

Depending on the specimen type, ASTM D412 offers two testing techniques. Please keep in mind that the findings of these two testing procedures are not equivalent.

The “dumbbell” or “dogbone” shaped specimens are used in ASTM D412 Method A, while ring-shaped specimens are used in ASTM D412 Method B.

ASTM D412 Method A, which uses a dumbbell or dogbone-shaped specimen, is the most popular.

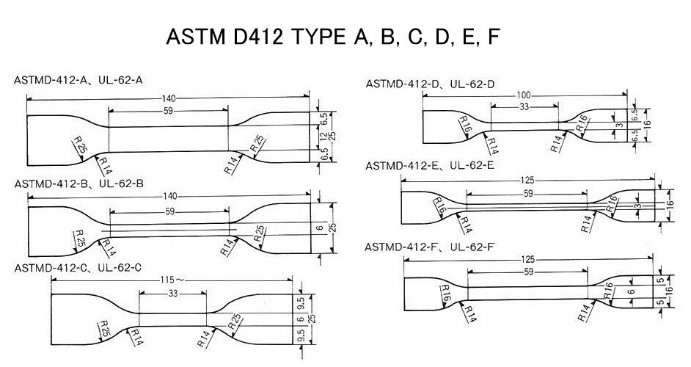

In ASTM D412 Method A, there are six different sorts of dogbone specimens. The technique A type C dogbone specimen is the most common of all specimen types.

ASTM D412 Method B, a ring-shaped specimen is use. There are two cut ring specimens.

The findings of ASTM D412 Method B will not be the same as those of ASTM D412 Method A.

The usage of ASTM D412 Test Method A is more common than the use of ASTM D412 Test Method B. Die cuts from an injection molded sheet or plaque is require for dogbone specimens.

The direction in which the sheet is extruded matters because it affects the grain pattern of the material. All specimens should be cut with the longitudinal area parallel to the grain for consistency. Victor also supplies the specimen die cutter according to ASTM D412.

ASTM D412 SPECIMEN DIMENSION

For ASTM D412 testing, there are six different types of dogbone specimens and two different types of cut ring specimens. A die-cut C dogbone specimen with an overall length of 115 mm (the gauge length being 25 mm), a width of 6 mm, and a thickness of 3 mm is the most typically examined shape.

The ASTM D412 specimen’s thickness must be measure three times, with the median value being considered acceptable.

All specimens used for ASTM D412 testing must be measure with a micrometer in accordance with ASTM D3767 to confirm conformity with the standard.

SPECIMEN ALIGNMENT

ASTM D412

Specimens must be held perpendicular to the jaw faces and not tilted at an angle during testing.

Specimen misalignment can lead to significant differences in test findings, thus it’s important to make sure that all of the specimen are aligned consistently for each test.

Using a jaw face that is close to the same width as the ASTM D412 specimen, making it relatively straightforward to visually change alignment, is one technique to correct misalignment. Using a specimen alignment device that mounts directly onto the grip bodies is the simplest solution to avoid misalignment. This is a simple bar with an adjustable stopping point that allows operators to readily determine if their ASTM D412 specimen is properly aligned.

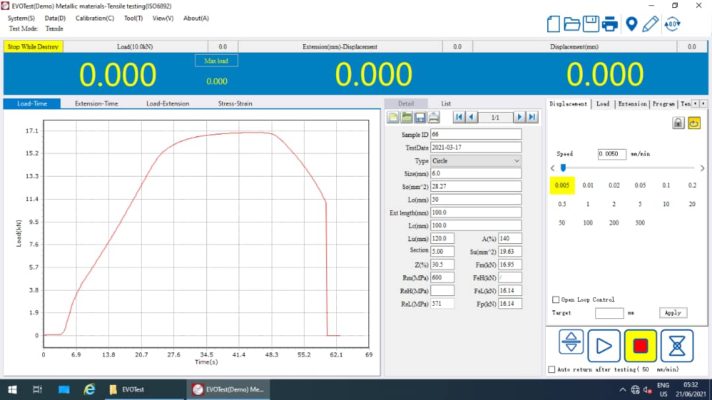

SOFTWARE

Victor Universal Testing Machine comes with software that includes several testing modes and test standards such as ASTM D412 upon purchase. Users can choose the pre-configured test methods and supporting documentation to assist with testing to various standards, including ASTM D412 for those who plan to test Elastomers.

ASTM D412 UNIVERSAL TESTING MACHINE

• VEW260 Series

Single Column Digital Touch Screen Control Universal Testing Machine For ASTM D412

Single Column Computer Controlled Universal Testing Machine for ASTM D412

-

VEW2308 Series

Double Column Computer Controlled Universal Testing Machine for ASTM D412

LCD Touch Screen-controlled Universal Testing Machine

ASTM D412 UNIVERSAL TESTING MACHINE FIXTURES/GRIPS

- Roller Grip

- Pneumatic Grip

ASTM D412 STRAIN/ELONGATION MEASUREMENT

• Long Travel Extensometer

ASTM D412 UNIVERSAL TESTING MACHINE SOFTWARE

• EVOTest

ASTM D412 SPECIMEN PREPARATION AIDS

• Die Cutter